Explosion isolation valves are an effective solution for protecting industrial facilities and personnel from destructive, explosive events.

Such valves are designed to limit the spread of combustible dust and vapour explosions throughout a facility, helping to ensure the safety of both personnel and equipment. If you are in search of an explosion isolation valve system, you may contact Coopatex.

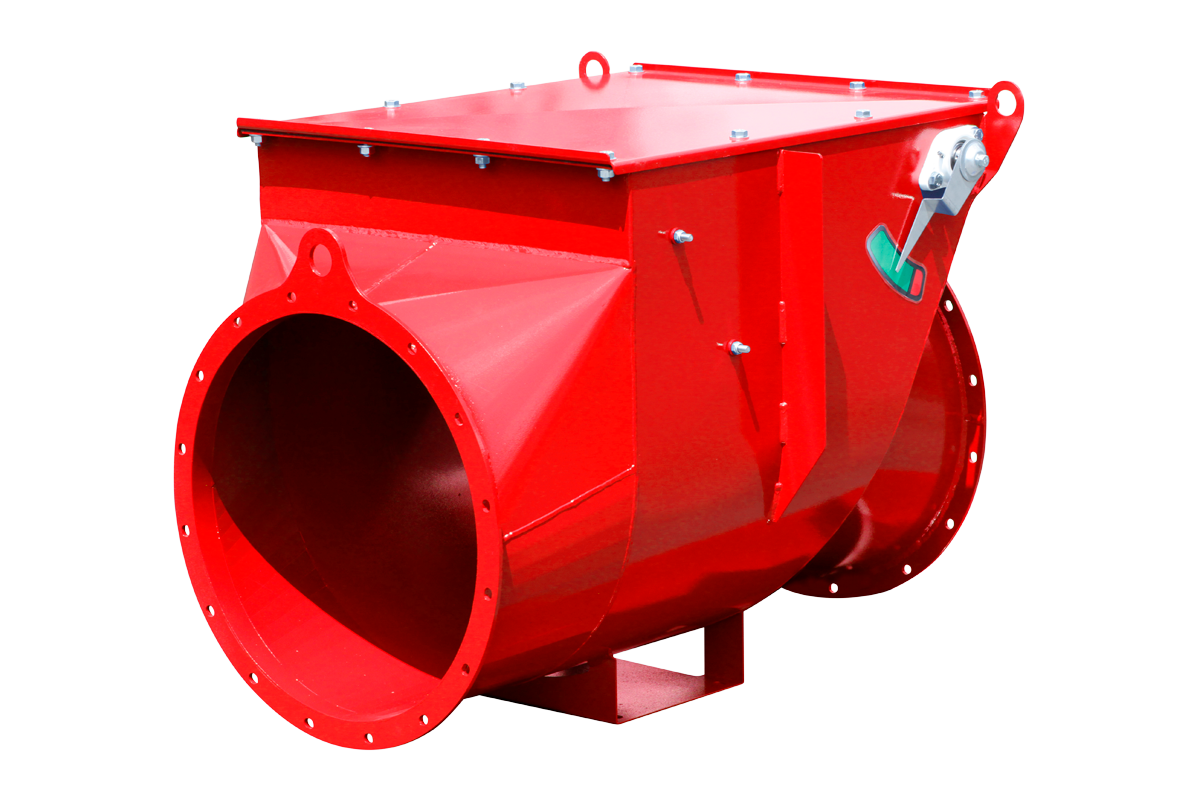

Image Source: Google

How Explosion Isolation Valves Work?

Explosion isolation valves are typically designed with a double-sealed flap system. In the event of a combustible dust or vapour explosion, the valve opens to release pressure and isolate the explosion to the affected area.

The valve’s flap system is designed to open and close quickly, limiting the spread of the explosion and preventing damage to other areas of the facility. The valve is then reset and ready for use again.

Benefits

Explosion isolation valves provide numerous benefits for industrial facilities. Not only do they help to limit the spread of combustible dust and vapour explosions, but they also help to protect personnel and equipment from damage and injury.

Additionally, explosion isolation valves are cost-effective and can be easily installed in existing systems.

Conclusion

Explosion isolation valves offer a reliable solution for protecting personnel and equipment from combustible dust and vapour explosions. Their quick-acting flap system helps to limit the spread of the explosion and prevents damage to other areas of the facility.